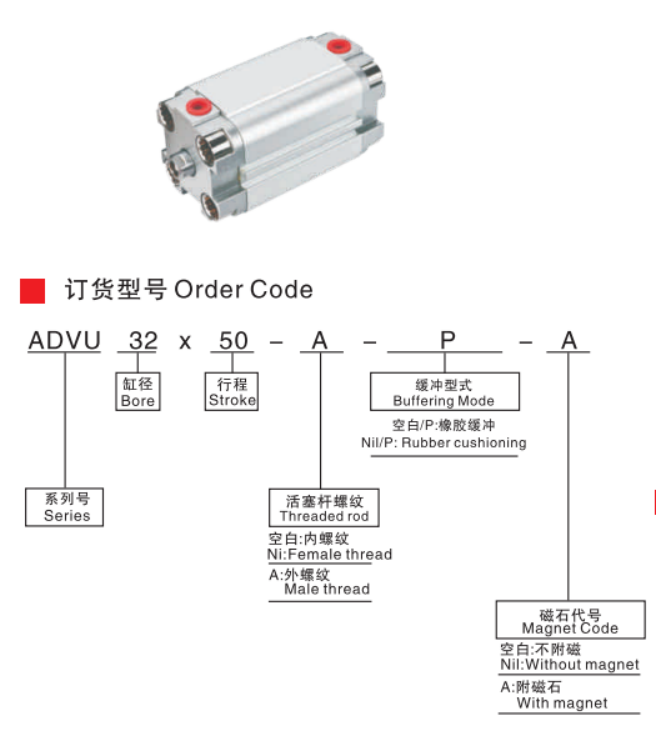

ADVU Series aluminii mixturae compactionis typus vexillum pneumaticum aeri cylindrici compactum

Product Description

Advu series cylindrorum signaculae designatae compactae sunt, structurae simplices et compactae, et facile inaugurare et conservare. Proprietas subtilitatis et magnae fidei habet, et in variis ambitus asperis stabiliter operari potest.

Huius seriei cylindrici ambitus impulsus est dilatatus, et opportunum exemplar seligi potest secundum varias applicationes requisita. Amplis pressionibus et caliditatibus laborat, et variarum industrialium agrorum necessitatibus occurrere potest.

Advu series cylindrici proprietates longae vitae habent, strepitus humilis et energiae humilis consumptio, quae efficientiam producendi emendare et consummationem energiae minuere possunt. In machinis fabricandis, autocinetis fabricandis, instrumentis electronicis aliisque agris late adhibetur ac validum subsidium praebet ad variarum industriarum productionem automatice.

Technical Specification

| Bore Size (mm) | 12 | 16 | 20 | 25 | 32 | 40 | 50 | 63 | 80 | 100 |

| Modus agendi | Duplex Actus | |||||||||

| Operatio Media | Purgatus Air | |||||||||

| Opus Pressura | 0.1~0.9Mpa(kgf/cm²) | |||||||||

| Probatur Pressura | 1.35Mpa(13.5kgf/cm²) | |||||||||

| Operatio Temperature | -5~70℃ | |||||||||

| Buffering Modus | Pulvinar Flexilis | |||||||||

| Portus Location | M5 | 1/8 | 1/4 | |||||||

| Corpus Material | Aluminium Alloy | |||||||||

| Modus / Bore Location | 12 | 16 | 20 | 25 | 32 | 40 | 50 | 63 | 80 | 100 |

| Sensor Switch | CS1-M | |||||||||

Plaga Cylindri

| Bore Size (mm) | Standard Stroke(mm) | Max.Stroke (mm) | Permissa Stroke (mm) | |||||||||

| 12 | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 50 | 60 |

| 16 | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 50 | 60 |

| 20 | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 80 | 90 |

| 25 | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 80 | 90 |

| 32 | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 130 | 150 |

| 40 | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 130 | 150 |

| 50 | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 130 | 150 |

| 63 | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 130 | 150 |

| 80 | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 130 | 150 |

| 100 | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 130 | 150 |

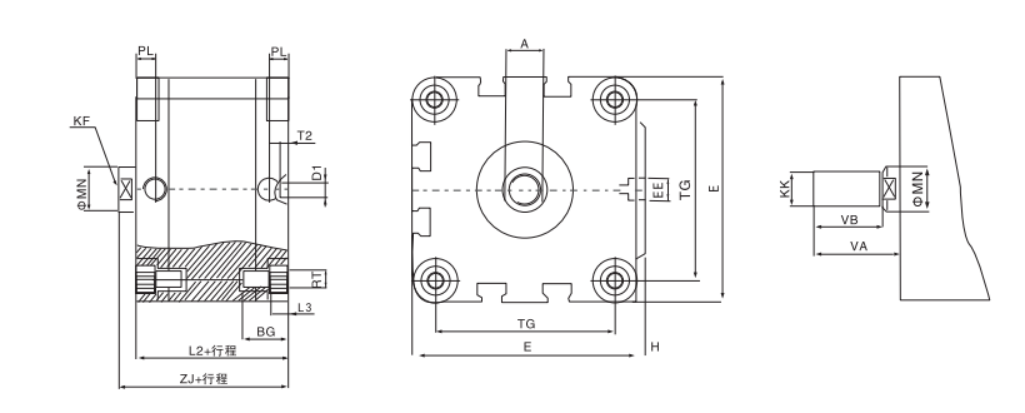

Dimension

| Code Exemplar | A | BG | D1 | E | EE | H | L2 | L3 | MM | PL | RT | T2 | TG | VA | VB | ZJ | KK | KF |

| 12 | 5 | 18.5 | 6 | 29 | M5 | 1 | 38 | 3 | 6 | 8 | M4 | 4 | 18 | 20.5 | 16 | 42.5 | M6 | M3 |

| 16 | 7 | 18.5 | 6 | 29 | M5 | 1 | 38 | 3 | 8 | 8 | M4 | 4 | 18 | 24.5 | 20 | 42.5 | M8 | M4 |

| 20 | 9 | 18.5 | 6 | 36 | M5 | 1.5 | 39 | 4 | 10 | 8 | M5 | 4 | 22 | 26.5 | 22 | 43.5 | M10*1.25 25 | M5 |

| 25 | 9 | 18.5 | 6 | 40 | M5 | 1.5 | 41 | 4 | 10 | 8 | M5 | 4 | 26 | 27.5 | 22 | 46.5 | M10*1.25 25 | M5 |

| 32 | 10 | 21.5 | 6 | 50 | G1/8 | 2 | 44.5 | 5 | 12 | 8 | M6 | 4 | 32 | 28 | 22 | 50.5 | M10*1.25 25 | M6 |

| 40 | 10 | 21.5 | 6 | 60 | G1/8 | 2.5 | 46 | 5 | 12 | 8 | M6 | 4 | 42 | 28.5 | 22 | 52.5 | M10*1.25 25 | M6 |

| 50 | 13 | 22 | 6 | 68 | G1/8 | 3 | 48.5 | 6 | 16 | 8 | M8 | 4 | 50 | 31.5 | 24 | 56 | M12*1.25 25 | M8 |

| 63 | 13 | 24.5 | 8 | 87 | G1/8 | 4 | 50 | 8 | 16 | 8 | M10 | 4 | 62 | 31.5 | 24 | 57.5 | M12*1.25 25 | M8 |

| 80 | 17 | 27.5 | 8 | 107 | G1/8 | 4 | 56 | 8 | 20 | 8.5 | M10 | 4 | 82 | 40 | 32 | 64 | M16*1.5 | M10 |

| 100 | 22 | 32.5 | 8 | 128 | G1/4 | 5 | 66.5 | 8 | 25 | 10.5 | M10 | 4 | 103 | 50 | 40 | 76.5 | M |